Double Compost

Overview

Technical Overview

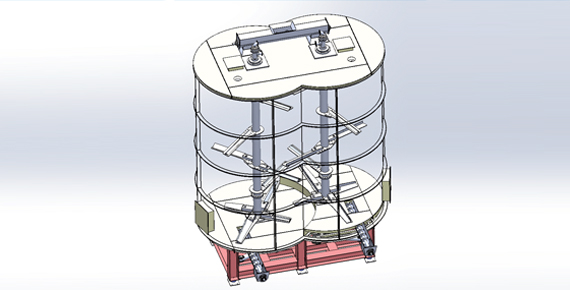

– Two-axes structure that has shortened stirring blades to reduce load and maximize ventilation.

– Two cylinders are combined to secure a wide fermentation volume.

– Maximize efficiency of air supply line and air pipe.

– Various kinds of animal manure can be fermented thanks to the excellent ventilation.

– Prefabricated structure transferred right after assembling in the factory,quality is guaranteed and construction period can be shortened.

– Convenient operation – weight reduction device installed on the main body enables to check fermentation status in real-time.

Structure

– Due to the cross sectional structure of two cylinders connected in parallel, it can provide a large processing capacity twice as much as other companies’ products. And the load resistance is minimized by short stirring blades, which enables to maximize the fermentation efficiency with optimal stirring.

– It is designed to stir the internal organic matter in 4 to 6 stages by a two-axis stirrer to uniformly bring air into contact so that it can ferment at high speed while improving the porosity.

Essential Elements of Fermentation

In order to aerobically ferment organic matter, fermentation elements such as moisture,

temperature, air, pH, nutrient and C/N ratio should be secured. Especially moisture,

temperature, air and nutrient are essential for aerobic fermentation.

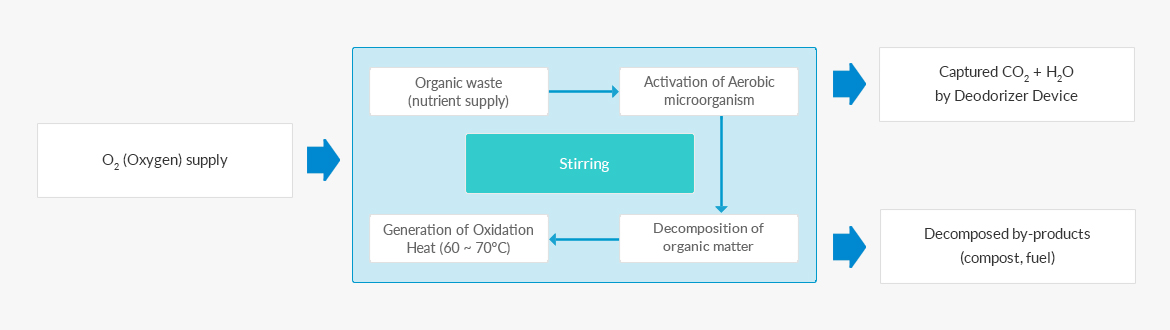

Principle of Fermentation

Aerobic microorganisms (air-loving microorganisms) residing in organic matter is optimally activated when air is added to and stirred in organic matter (e.g. food waste, sewage sludge, industrial wastewater sludge, livestock manure sludge, livestock byproducts).

Through this process, the organic matter is decomposed and oxidation heat is generated to raise temperature and evaporate water, reducing the moisture and the volume accordingly.

What is remained after all this process is the byproducts, which can be used as the compost raw materials or the source for fuel.

As the byproducts is fermented at a high temperature of 60 ~ 80 ℃ for about 7 days, a bad gas or various kinds of harmful substances is already eliminated so that it can effectively resist against the AI (Avian Influenza).

Process of Fermentation

Effects of Fermentation

The inside of “Double Compost” is divided into three parts : discharge stage, fermentation stage and input stage, so as to activate the microorganisms contained in organic matter in the shortest time through consecutive actions of air supply, stirring, and ventilation and further to make it possible to maintain a stable fermentation process.

In particular, thanks to a large volume of the fermentation tank, it can flexibly respond to changes in some substances of the input.

Discharge status after fermentation of chicken manure

Discharge status after fermentation of cow manure

Discharge status after fermentation of pig manure

Advantages of High-Speed Fermentation Machine

Direct input of raw manure

– Fermentation of raw manure (75% wt of hog manure, 65% wt of chicken manure)

– No moisturizer used

Efficient operation and management

Weight reduction device is embedded to check the fermentation progress at any time

A Simple stench removal

Easy to remove the dust through the exhaust-collecting structure

Installable indoors and outdoors

Vertical cylindrical structure allows installation anywhere in or outside of the space

A high throughput fermentation structure

Massive fermentation is possible with a structure of large volume space

Possible to recycle all the processed byproducts

– Processed byproducts is quality ingredients for organic fertilizer

– Possible to purchase the total byproducts regardless of time

Highly durable and insulating material

Used high-quality materials for premium and stable products

Available for government support and policy funds

Providing a consultation on various ways for farmers to save costs

Expected Effects

Technical aspect

– Secure eco-friendly pre-treatment technology for organic waste

– Advance disposal technology of livestock manure

– Diversify resources of livestock manure

Economical aspects

– Reduce cost through self-processing of organic waste

– Create new revenues from by products

– Improve the efficiency of manure treatment

Social aspects

– Eliminate complaints by reducing stench in the livestock farms

– Establish a resource recycling society with the expansion of waste recycling

– Implement an eco-friendly workplace

Environmental aspects

– Improve working environment for livestock farms

– Reduce stench and incidence of various diseases

– Contribute to a clean hygienic status of livestock farms

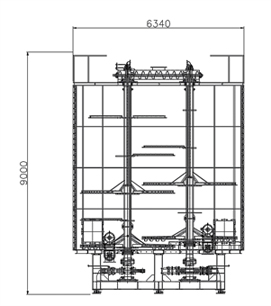

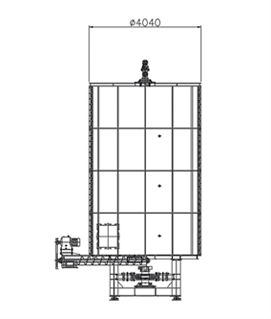

Product Specification

| Item | MC-120D | |

|---|---|---|

| Size | W x L x H | 6,340 x 4,040 x 9,000 |

| Total volume (m3) | 120 | |

| Stirring speed (rpm) | 0.25 | |

| Number of Stirring Blades | 5 | |

| Number of Tubular Body (layer) | 4 | |

| Amount of Supply (m²/min) | 30 | |

| Hydraulic Motor (kw) | 15 | |

| Blower Motor (kw) | 30 | |

| Output Screw (kw) | 3.5 x 2 | |

| Input Screw (kw) | 3.5 | |

| Installation Area | 82.5-square-meter | |

| Regular Power (kw) | 37 | |

| Irregular (Emergency) Power (kw) | 40.5 | |

| Total Power Consumption (kw) | 77.5 | |