Deodorizer Machine

MUJIN Techno Deodorizer Device System

-

Cyclone dust collector

A device primarily collecting and removing the dust with only gas and steam discharged by applying the centrifugal force to the gas containing heavy particles to separate the particles apart from the gas.

-

Turbo blower

1. Excellent durability and perfect sealing – endurable even in high humidity, moisture and dust

2. Made of special material considering corrosion resistance

3. High efficiency with good wind pressure and wind power -

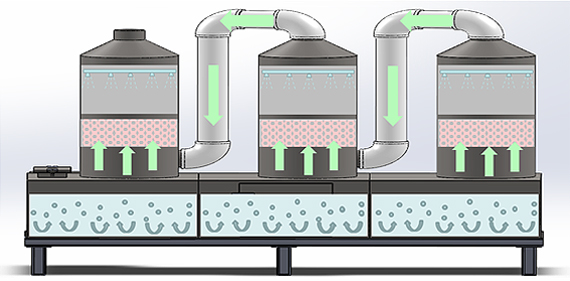

Deodorizing Tower

1. It is a device that mechanically implements a water circulation system that most economically suppresses typical gases (ammonia, methane, hydrogen sulfide gas), which are often generated during the fermentation process.

2. When air is injected into the water, the water-soluble reaction occurs due to the aeration, and then the effect of deodorization is maximized with the enhanced capturing by the three-stage filter and fine injection method.

3. It is an economical system that is easy to operate, easy to operate and maintain.

Specification

| Item | Size | |

|---|---|---|

| Size | L × W × H | 3,720 x 2,600 × 3,200 |

| Total(m3) | 2.5 | |

| Supply(㎥/min) | 50 | |

| Turbo blower(kw) | 7.5 | |

| Circulation pump(KW) | 2.3 | |

| Total power consumption(kw) | 9.8 | |

Technical Description

1

Unlike other products, fine contaminants and steam that have passed through the cyclone are transferred to the micro-injection pipe inside the deodorizer through the turbo blower and aerated with water.

It maximizes the water-soluble reaction by ensuring sufficient contact with the surface area increased as much as possible during fine spraying.

Gas and steam is significantly reduced by mutual diffusion.

2

The deodorizer of Mujin Techno increases the residence time of the residual gas and steam by passing through the three-stage filler and liquid dispersion device, thereby maximizing the gas-liquid contact time.

It is a method to remove odor by using a combination of wet aeration cleaning and filler liquid dispersing device, which not only satisfies the strengthened standards for preventing odor, but also exhibits excellent efficiency in removing high concentration odor.

In addition, the maintenance cost is lowered through the recycling method.

3

Since the moisture released and evaporated from the fermenter is more than about 3 tons per day, the water in the deodorizer tank should be discharged.

The internal water discharge from the deodorizer tank is carried out by opening the over valve and discharging the water after precipitating the internal water through the septic tank.